Gal Grating

Electroforged Gratings, Stainless Steel Gratings, Galvanized Gratings, Heavy Duty Gratings, Non-Ferrous Gratings, and Fiber Glass Gratings are just a few of the products we make.

Electroforged Gratings, Stainless Steel Gratings, Galvanized Gratings, Heavy Duty Gratings, Non-Ferrous Gratings, and Fiber Glass Gratings are just a few of the products we make.

Electroforged grating is produced using PLC-controlled equipment that combines high hydraulic pressure (over 100 tonnes) and a high electric current (approximately 2200 amps) to fuse the cross and bearing bar into a seamless joint.

V D Zincare produces Stainless Steel Gratings in a variety of sizes and specifications. The raw materials used in the manufacture of gratings must be certified to AISI 304/AISI316 OR 309, or as specified by you.

Mild steel, stainless steel, and aluminium are used. We provide all material handmade gratings with required cut outs based on customer drawings. We fabricate sizes ranging from 250 mm to 1200 mm in width and length as required by the user.

Heavy Duty Welded Gratings are intended for use in applications with high rolling and static loads, such as highways, plant floors, loading docks, inlet covers, and airport runways. Because these conditions can range from light-duty forklifts to heavy-duty truck or aircraft traffic, a variety of bar sizes and spacings are available.

Regular Expansion Metal is a finished open mesh product that is die-cut and expanded as it moves through progressive dies on a press. The metal can be expanded up to ten times its original size, losing up to 80% of its original weight per square foot while retaining form and rigidity.

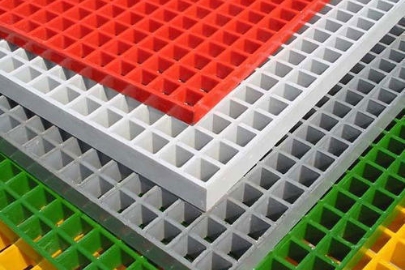

For many applications, fibreglass grating is an appealing, low-maintenance alternative to metal grating. Because fibreglass grating weighs much less than steel, it is less expensive to transport and instals easily with only basic hand tools. Superior strength and load-bearing capability are provided by the rigid glass-reinforced plastic resin structure.